No matter if you’re a DIY enthusiast or a seasoned artist, a tufting gun is an indispensable tool for producing beautiful tufted designs. Your tufting gun must be regularly cleaned and maintained in order to function at its best and last a long time. In this thorough guide, we’ll give you helpful hints and pointers for caring for your tufting gun so you can keep creating stunning tufted works of art with ease. We can help you with everything from basic cleaning procedures to troubleshooting typical problems. Let’s start now!

Sadržaj dokumenta

ToggleWhy Cleaning and Maintaining Your Tufting Gun is Crucial

Your tufting gun needs to be cleaned and maintained properly for a number of reasons:

Increases the Durability of Your Tufting Gun

Your tufting gun’s lifespan can be increased with regular cleaning and maintenance. You can prolong the life of its components and keep it in excellent working order for years by keeping it free of dirt, dust, and debris.

Obtains the Best Performance

Tufting guns work best when they are clean. Dust and debris can jam the yarn or cause uneven loops by clogging the mechanism and interfering with how smoothly the fabric is tufted. A consistent and high-quality tufted design is ensured by proper maintenance.

Avoids Yarn Breaks and Snags

If there are obstacles or rough surfaces inside the tufting gun, yarn snags and breaks may happen. These problems can be avoided with routine cleaning, which lowers the likelihood that your tufting projects will be interrupted in an expensive and time-consuming way.

Health and Hygiene

A clean tufting gun is safer and more hygienic to use. The tufting gun may become clogged with dust and dirt, which could irritate you or degrade the quality of your tufted designs. A healthier working environment is ensured by keeping your tufting gun clean.

Cleaning Your Tufting Gun: Step-by-Step Guide

Maintaining your tufting gun in top condition and making sure it works at its peak during your creative endeavors require proper cleaning. The cleaning procedure is a crucial component of your tufting routine because a clean tufting gun will produce tufted designs that are consistent and of high quality. Let’s examine a thorough, step-by-step tutorial for effectively cleaning your tufting gun:

Collect the Required Equipment and Materials

Bring together all the required equipment and materials before you start cleaning your tufting gun. Having everything prepared will speed up the procedure and guarantee that you have uninterrupted time to thoroughly clean your tufting gun. What you’ll need is as follows:

Soft brush or toothbrush: To clean the various parts of your tufting gun of dust, dirt, and debris, use a soft-bristled brush or toothbrush.

Lint-free cloth: To clean and dry the tufting gun without leaving lint or residue behind, a lint-free cloth is necessary.

Isopropyl alcohol or a mild cleaning solution: Isopropyl alcohol works well to clean the tufting gun of dirt and grime. Alternately, you can use a gentle cleaning solution that the manufacturer suggests.

Small bowl or container: Hold the cleaning solution while you clean the tufting gun in a small bowl or container. Needle-nose pliers can be used to untangle any tangled or stuck yarn from the needle area.

Cut the Tufting Gun off.

Safety is the most important factor to consider while cleaning. Make sure your tufting gun is unplugged from its power source before you begin cleaning it. The risk of injury is decreased by unplugging the tufting gun, which prevents any accidental activation while you work on it.

Get Rid of Extra Yarn and Junk

Examine your tufting gun carefully, paying attention to any areas where yarn or other debris may have amassed. A soft brush or toothbrush should be used to start by removing any visible excess yarn or threads. Be gentle to prevent breaking any parts of the tufting gun.

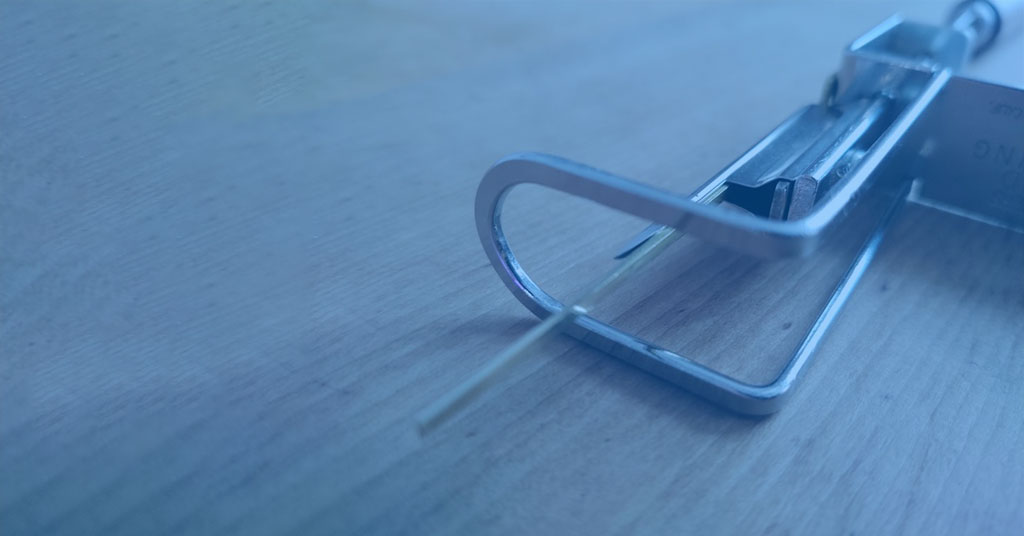

Clean the Cutting Blade and Needle

Your tufting gun’s needle and cutting blade are crucial parts that need to be cleaned thoroughly. Any buildup or residue on these components, which come into direct contact with the tufting yarn, may interfere with the tufting operation.

Dip a cotton swab or lint-free cloth in isopropyl alcohol or another gentle cleaner. Clean the needle and cutting blade thoroughly to get rid of any debris, lint, or yarn buildup. Wipe the surfaces gently, making sure to get into all the cracks and crannies.

Thoroughly clean the yarn feeding system

The tufting yarn is fed through the tufting gun by the yarn feeding mechanism. This area is susceptible to dust and debris buildup over time, which can impair the tufting procedure’s smoothness.

To get rid of any possible dirt or debris, clean the yarn feeding mechanism with a soft brush or toothbrush. Make sure there are no obstructions near the yarn feeding hole by paying close attention to the area there.

Lubricate Any Moving Parts (If Needed)

Some tufting guns have moving components that might need lubrication to operate smoothly. For information on the right lubricant to use and how to apply it properly, consult the manufacturer’s instructions.

Use a small amount of the suggested lubricant on the designated parts of your tufting gun if it needs to be lubricated. Avoid overlubricating because it can attract dirt and dust, which could cause problems.

Test the tufting gun

Reconnect the tufting gun to its power source after cleaning is finished, then test it out. To check that everything is working properly and that the tufting gun is operating smoothly, run it without any yarn.

Check for any odd noises, vibrations, or tufting process problems during the test run. Your tufting gun is now clean and prepared for your next tufting project if everything seems to be in working order.

Regular Maintenance Cleaning

Your tufting gun should be part of a regular maintenance schedule; how frequently you clean it will depend on how often you use it and the amount of dirt and debris it accumulates. If you use your tufting gun frequently, consider cleaning it after each use or at least once a week. Regular cleaning helps prevent dirt and debris from accumulating and ensures that your tufting gun remains in optimal condition.

Tips for Troubleshooting and Maintaining Your Tufting Gun

Your tufting gun is a useful tool that enables you to make lovely tufted designs with accuracy and simplicity. Regular maintenance and troubleshooting are necessary to guarantee that your tufting gun keeps working at its peak level and lasts for many imaginative projects. This section will go into great detail with advice on how to maintain your tufting gun and troubleshoot typical problems.

Resolving Clogged Yarn

Jammed yarn is one of the most frequent problems you might run into when using a tufting gun. When the tufting yarn gets tangled up or caught in the needle area or the yarn feeding mechanism, a jam happens. To deal with tangled yarn:

Cut off the power source.

Disconnect the tufting gun from its power source the moment you notice a jam. In order to avoid accidental activation while troubleshooting, this is an essential safety measure.

Examine the Needle Area

Gently remove any tangled or jammed yarn using your fingers or needle-nose pliers after carefully checking the needle area of your tufting gun.

Get Rid of the Yarn Feeding Device

Next, look for any obstructions or tangled yarn in the yarn feeding mechanism. To remove any dirt or debris that might be impairing the yarn’s ability to move smoothly, use a soft brush or toothbrush.

Make a test run

Reconnect the tufting gun to its power source after clearing the jam, then run a test run without yarn to make sure the jam has been fully fixed. During the test run, listen for any odd vibrations or sounds.

Finding any loose screws or other components

Your tufting gun’s stability and performance may be impacted over time by frequent use loosening screws and other parts. To make sure that no parts or screws are loose:

Examine the Outside

Check the exterior of your tufting gun visually for any missing or dangling parts or screws. With the proper tools, gently tighten any slack screws.

Check for vibrations

Keep an eye out for any unusual rattling or vibrations while using your tufting gun. These might be indicators of parts that need to be tightened up.

Storage Techniques

Your tufting gun must be stored properly to remain functional and long-lasting. When not in use, keep your tufting gun clean, dry, and away from moisture and other contaminants.

Use the original container or a protective one.

To store your tufting gun, think about using the original packaging or a protective case. This protects it from dirt and unintentional harm.

Keep away from humid conditions

High humidity shouldn’t be used to store your tufting gun because moisture can cause internal components to corrode.

Replace Damaged or Worn Parts

Check your tufting gun frequently for indications of wear or damage, such as bent needles, dull cutting edges, or cracked parts. If you spot any worn-out or harmed components:

Consult the manufacturer’s instructions

To find compatible replacement parts for your tufting gun, refer to the manufacturer’s instructions or the user manual.

Use genuine replacement parts

Always choose genuine replacement parts from the manufacturer when replacing components. Non-original components could cause your tufting gun to malfunction or fit incorrectly.

Arrange for Professional Upkeep

Consider scheduling routine professional maintenance checks with the manufacturer or a skilled technician for professional-grade or heavy-duty tufting guns.

Benefits of Professional Upkeep

By having your tufting gun professionally maintained, you can be sure that it will be thoroughly inspected, cleaned, and any potential problems will be resolved by trained technicians.

Observe the advice of the manufacturer

To keep your tufting gun in excellent condition and avoid significant issues, adhere to the manufacturer’s recommended maintenance schedule.

Lubrication, if necessary

Some tufting guns might have moving components that need to be lubricated every so often to ensure smooth operation. Lubrication assists in lowering friction and component wear. If lubrication is necessary for your tufting gun:

Use the Recommended Lubricant

For information on the proper lubricant to use, consult the manufacturer’s instructions. Use only lubricants that the manufacturer has approved; anything else could harm the tufting gun.

Use Lubricant Moderately

Utilize the lubricant sparingly on the designated parts as directed by the manufacturer. A surplus of lubrication may attract dust and debris and cause problems.

Delete Extra Lubricant

To avoid the lubricant dripping onto other components of the tufting gun after application, wipe away any excess with a lint-free cloth.

Test Run Following Upkeep

Always test your tufting gun to make sure it is working properly and without any issues after carrying out any maintenance or troubleshooting.

Run without Yarn

In order to prevent any potential snags or jams, run the test run without yarn. Watch how the tufting gun works and listen for any odd vibrations or sounds.

Fine-tune and adjust-Tune

Before starting your tufting projects, fix any problems you find during the test run by making the necessary adjustments or tweaks.

Continual Cleaning Procedures

To stop dust and debris from accumulating on your tufting gun, establish a regular cleaning schedule. Depending on how frequently you use it, cleaning your tufting gun after each use or at least once a week will help it continue to operate at its best.

Comply with the Cleaning Procedures in Detail

To properly clean your tufting gun, adhere to the step-by-step cleaning instructions provided earlier in this article.

Keep the tufting gun dry

To avoid corrosion after cleaning, make sure your tufting gun is completely dry before storing it.

Store in a Clean Environment

To reduce the chance of dust and dirt accumulating, store your tufting gun in a spotless area.

Cleaning and Maintaining Your Tufting Yarn

To achieve the best results in your projects, it’s crucial to take care of your tufting yarn in addition to cleaning your tufting gun. Here are some pointers for caring for your tufting yarn:

Properly store yarn

Keep your tufting yarn cool and dry, away from moisture and direct sunlight. The yarn is kept neatly stored to avoid tangling or dust accumulation.

Look for tangles or knots

Check for knots or tangles before loading the yarn into your tufting gun. To ensure smooth tufting, carefully untangle the yarn.

Watch your yarn usage.

To determine when to restock, keep track of how much tufting yarn you use each day. Workflow disruption can result from running out of yarn in the middle of a project.

Verify for consistency in color

Make sure the color is uniform if you’re working on a big project that calls for several skeins of the same color of yarn. Your tufted design’s final appearance can be impacted by minute differences between dye lots.

Select Superior Yarn

Purchase long-lasting, colorfast tufting yarn of the highest caliber. Tufted designs made from high-quality yarn are more vibrant and durable.

Conclusion

Any enthusiast who enjoys tufting should regularly clean and maintain their tufting gun and yarn. Regular cleaning ensures peak performance, prevents common problems like jammed yarn and snags, and extends the life of your tufting gun.

You can maintain your tufting gun in excellent condition and continue effortlessly creating beautiful tufted designs by adhering to the step-by-step cleaning guide and using the troubleshooting suggestions. Additionally, taking good care of your tufting yarn ensures that your tufted projects will turn out consistently well.

To keep your tufting gun in the best condition possible, remember to schedule routine maintenance checks and store your yarn properly. Your tufting gun and yarn will be your dependable allies in your artistic tufting journey for years to come if you keep them clean and maintained properly. Have fun tufting!